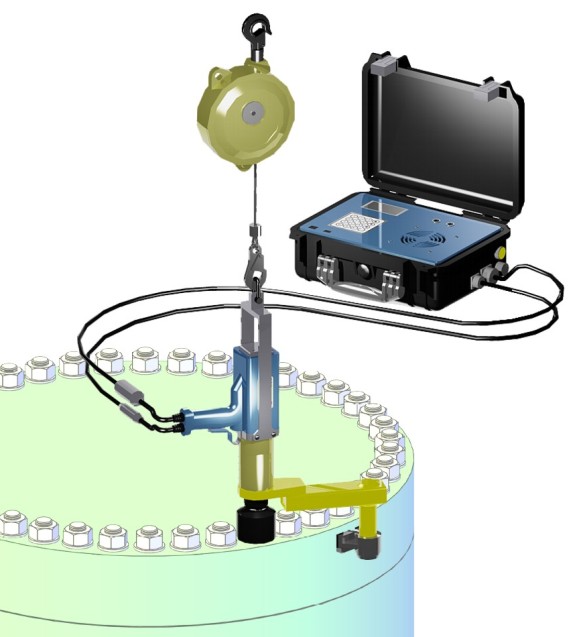

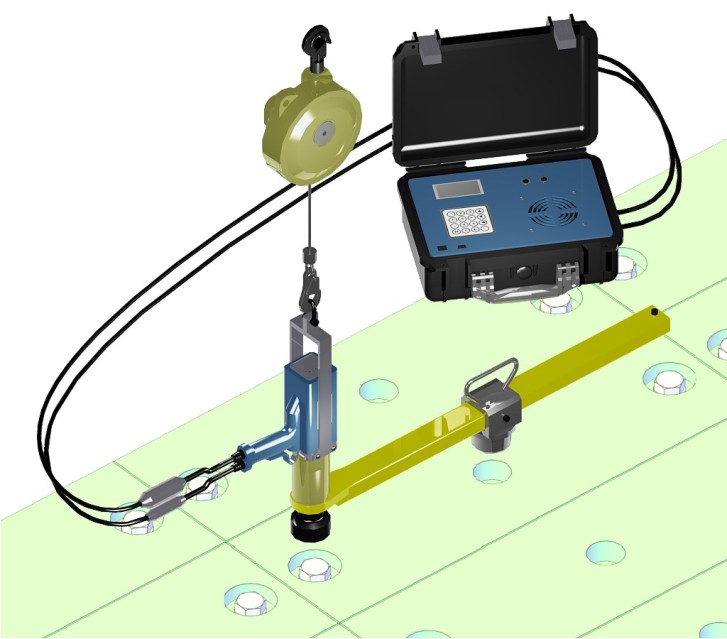

EC-RAD System

Customer: EDF Energy

Application:

- Tightening/Untightening Nuclear Fuelling Machine Bolts

Problem:

- The need for traceability of all bolt torque data

- Operating environment demands a high level of accuracy

- Other methods are time consuming and require a lot of manual effort

Solution:

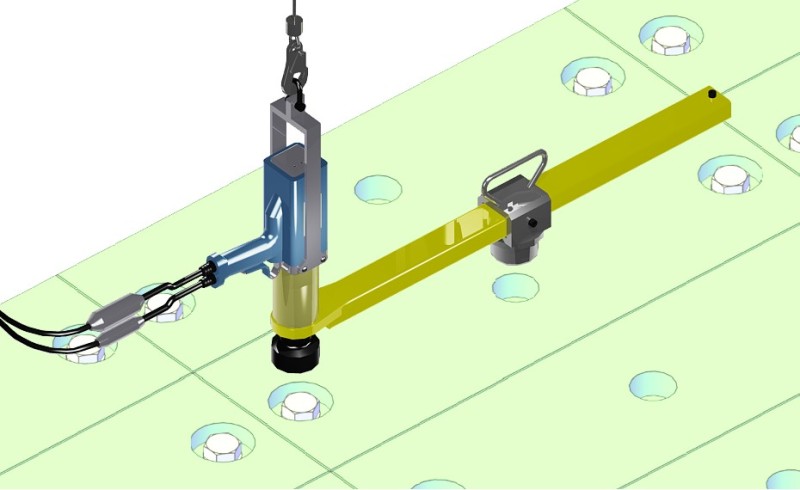

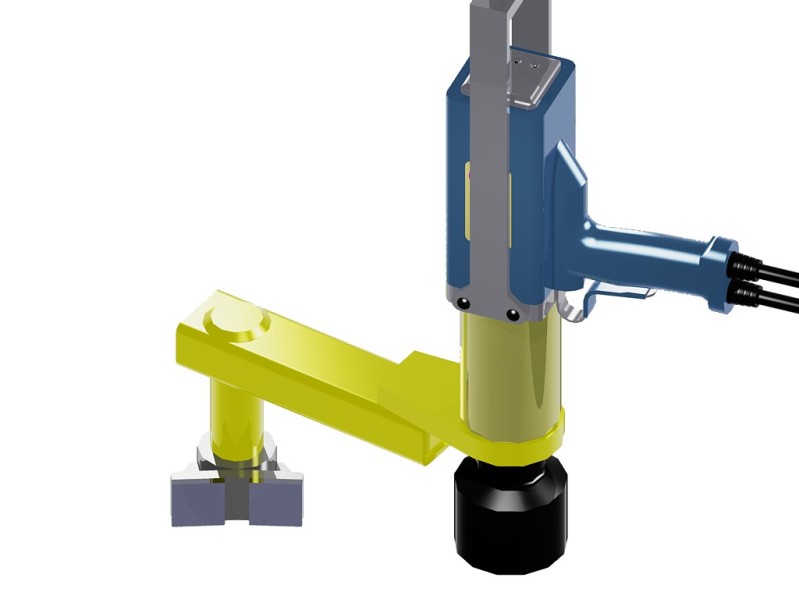

- EC-RAD Electric Torque System

Features:

- Soft start trigger for gradual acceleration

- Soft cover trigger allows positive dual finger activiation

- Safety release - tool stops on release of trigger

- Bi-directional operation -ergonomically positioned 'rocker' switch for quick selection between forward & reverse

- Low noise output - less than 70dB (A) in a free field environment

- Automatic two speed option

- Control panel is pass code protected to prevent unauthorised access to settings/parameters

Benefits:

- Automatic data collection of all torque activity (complete with USB connectivity to PC)

- Repeatability better than +/-4%

- No risk of oil contamination

- Non-impacting operation minimises noise & vibration

- Significantly reduces manual handling effort

- Much quicker than manual tooling

- Suitable for numerous high torque/high accuracy bolting applications